Trump orders GM to make coronavirus ventilators, which GM was already rushing to do

Updated at 5:22 EDT, March 27

On a day when the House of Representatives passed and President Trump signed into law a sweeping $2 trillion relief bill intended to mitigate the unprecedented economic damage caused by the coronavirus epidemic, another drama was playing out between the administration and General Motors, which ended when Trump invoked the Defense Production Act, seeking to force the automaker to make medical ventilators.

“Our negotiations with GM regarding its ability to supply ventilators have been productive, but our fight against the virus is too urgent to allow the give-and-take of the contracting process to continue to run its normal course,” read a White House statement explaining Trump’s first use of the Korean War-era act. “GM was wasting time. Today’s action will help ensure the quick production of ventilators that will save American lives.”

After Trump invoked the act, GM said its commitment to build Ventec’s ventilators “has never wavered.”

Even before Trump’s order, GM told Autoblog in a statement, “Ventec Life Systems and General Motors have been working around the clock to implement plans to build more critical care ventilators. With GM’s support, Ventec is now planning exponentially higher ventilator production as fast as possible.”

Trump has been reluctant to use the act to force businesses to contribute to the coronavirus fight, and still seemed ambivalent after issuing the order. “Maybe we won’t even need the full activation. We’ll find out,” Trump said Friday in the Oval Office.

The move appears aimed at price and volume negotiations. But it’s not even GM that’s negotiating with the Trump administration, it’s Ventec, said Chris Brooks, chief strategy officer for the company based in Bothell, Washington.

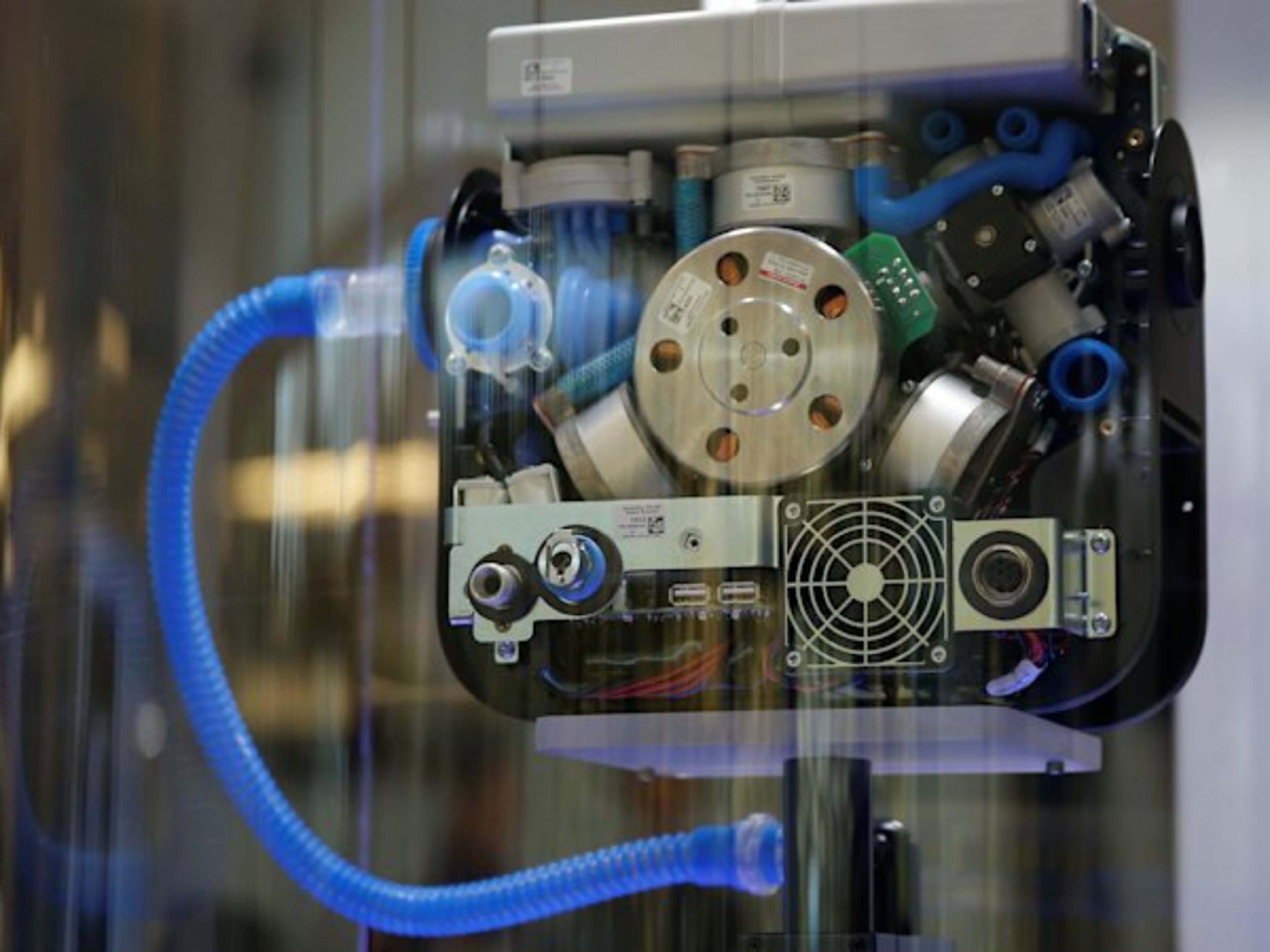

Ventec ventilators, which are portable and can handle intensive care patients, cost about $18,000 each, Brooks said. That’s much cheaper than the more sophisticated ventilators used by hospitals that can cost up to $50,000, he said.

The dispute first broke into public view last week, when Trump tweeted that the administration was in talks with GM and Ford about a role in making the medical devices to treat an expected surge in critically ill Covid-19 patients. Last Friday, GM and Ventec said they were already far along in the process, and were converting a GM electronics facility in Kokomo, Ind., to produce as many as 200,000 ventilators.

Then Thursday night, The New York Times broke a story that Trump had been set to make an announcement about the joint venture Wednesday — when the event was abruptly scrapped. The reason? The Federal Emergency Management Agency (FEMA) decided it needed more time to weigh the reported $1.5 billion price tag, including paying GM several hundred million dollars up front to retool the Kokomo plant for the task.

Government officials told The New York Times the GM-Ventec project might still happen, but they were looking at at least a dozen other proposals. They said they were struggling to understand how many units the new partnership would make because the number was in flux, and some officials were concerned about ordering too many ventilators and being stuck with an expensive surplus.

The move escalated a feud involving the president, GM, several governors and medical experts over the severity of the crisis and just how many ventilators will be needed to handle it.

Thursday night, Trump muddied the waters by questioning whether more ventilators were needed, at least for New York, currently the hardest-hit state in the country. Experts say close to 1 million ventilators could be needed nationwide at the pandemic’s peak, with fewer than 200,000 existing now at hospitals and in a federal strategic stockpile. In New York alone, Gov. Andrew Cuomo on Friday reported there have been 519 deaths and nearly 45,000 confirmed cases. Cuomo has cited health officials in saying 30,000 ventilators may be needed in New York, and he has been making that plea to the federal government all week — while New York hospitals are resorting to treating two coronavirus patients with a single ventilator and modifying anesthesia machines to serve as ventilators.

But Trump, in a Thursday night interview with Sean Hannity on Fox News, said he doubted New York needs the machines. “I have a feeling that a lot of the numbers that are being said in some areas are just bigger than they’re going to be,” he said. “I don’t believe you need 40,000 or 30,000 ventilators. You go into major hospitals sometimes, and they’ll have two ventilators. And now all of a sudden they’re saying, ‘Can we order 30,000 ventilators?’”

Cuomo’s retort: “You pick the 26,000 people who are going to die because you only sent 400 ventilators.”

By Friday morning, Trump seemed to sound an entirely different tone, tweeting orders to Ford and GM, and throwing a jab at GM CEO Mary Barra. He ended his tweet with “Invoke ‘P’,” foreshadowing his use of the Defense Production Act:

It should be noted that General Motors no longer owns the plant in Lordstown, Ohio, the president mentions above.

Trump also tweeted Friday morning that thousands of federally purchased ventilators had been found in storage in New York and he urged the state to put them to work, and that ventilators had been purchased from various companies, without detailing those claims.

GM fired back with a tweet of its own, noting in reference to FEMA’s concern about numbers that it will have the capacity to make more than 10,000 ventilators monthly, starting in April.

Trump’s tweet mentioned a number of 6,000 in April. In the GM-Ventec announcement, the automaker said its suppliers would begin delivering needed parts in early April. Considering the ramp-up time for those supply chains and for converting the Kokomo facility, if GM had promised the White House it could build 6,000 machines in April with a flow of 10,000 per month after that, the pace of the effort seems sufficiently urgent.

The other confusing aspect of Friday’s developments: The $2 trillion economic stimulus package, which includes a $500 billion fund to help industries that have struggled during the pandemic lockdown. Automakers are expected to tap into that fund. So the federal government stands ready to loan or give automakers billions of dollars, but seems locked in a negotiating battle over the cost of rapidly scaling up mass production of a lifesaving product. And on the automaker’s side of the negotiation, with its factories on coronavirus lockdown GM is currently desperate for cash.

Meantime, medical professionals insist the need for ventilators is urgent.

In addition to GM, Ford and Toyota are exploring ventilator production, and Nissan and Honda are working on the issue in Britain and could likely do the same in the U.S. if called upon.

In a press release Friday afternoon, Ford wrote, “We have started delivering tens of thousands of Ford-produced face shields to hospitals and police agencies, including the NYPD. We have teams working flat-out with GE Healthcare to boost production of simplified ventilators, and with 3M to increase the production of powered air purifying respirators. Ford is in active conversations with the Administration, seeking guidance about approvals, scope and distribution relating to a series of products, including ventilators. We’ll provide more detail on timing and production figures as soon as possible.”

Read the full New York Times story here.

The pandemic is raising all kinds of issues regarding just what is the cost of a human life. Here is a consideration of that question from fivethirtyeight.com. Meanwhile, some conservative voices are saying that getting the U.S. economy back on track is worth some loss of lives.

Material from The Associated Press was used in this report.